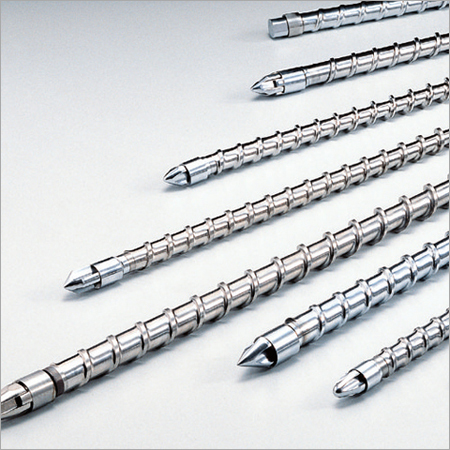

Segmental Screw Barrel

Segmental Screw Barrel Specification

- Noise Level

- Low

- Cutting Speed

- N/A (Not applicable to screw barrels)

- Spindle Speed

- Variable / Depends on Machine Design

- Power Source

- Electric

- Tool Type

- Plastic Processing Screw Barrel

- Application

- Plastic Extruder / Injection Moulding Machine

- Product Type

- Segmental Screw Barrel

- Material

- Alloy Steel / Nitrided Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Manual

- Drive Type

- Electric

- Voltage

- 220-415 V

- Weight (kg)

- 200 - 1000 kg (Depending on model & length)

- Dimension (L*W*H)

- Custom / As per machine specification

- Capacity

- Custom / Machine specific

- Feature

- Segmented construction for easy maintenance, Superior surface hardness, High wear resistance

- Color

- Metallic Silver / Grey

- Screw Diameter

- As per requirement (typically 25 mm - 150 mm)

- Packaging

- Wooden case or as per requirement

- Surface Treatment

- Nitrided / Hard chrome plated

- Barrel Length

- Up to 5 meters or customized

- Corrosion Resistance

- Yes

- Processing Type

- Extrusion / Injection

- Usage

- High production plasticizing, compounding, and extrusion operations

- Service Life

- Long working life with proper maintenance

- Customization

- Available as per client drawing and specification

- Section Type

- Segmented / Replaceable sections

- Mounting

- Horizontal

- Lining Material

- Bimetallic alloy optional

- Operating Temperature

- Up to 400°C

- Wear Resistance

- High

- Hardness

- 60-70 HRC (after heat treatment)

Segmental Screw Barrel Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 10 Sets Per Month

- Delivery Time

- 45 Days

- Main Domestic Market

- All India

About Segmental Screw Barrel

Bestowed with ISO 9001:2008 certifications, our firm is betrothed to manufacture and supply excellent quality range of Segmental Screw Barrel. This is mainly applied in injection moulding machines, plastic extrusion machines and rubber extrusion machines. Available in various lengths, diameters and finishes, this is manufactured by our dexterous professionals using the finest quality materials. Moreover, clients can avail this Segmental Screw Barrel from us at industry leading prices.

Features:

- It improves wear and superior corrosion resistance

- Resistant to corrosion

- Dimensional accuracy

Specification

|

Condition |

New |

|

Diameter (mm) |

20mm-200mm |

|

Appliance |

PVC, HDPE, PP, PE |

|

Application |

Plastics |

|

Screw Straightness |

0.015 |

|

Thickness |

2mm |

|

Surface Roughness |

Ra0.4 |

|

Screw Type |

Nitriding, Bimetallic, Chromeplate |

|

Hardness |

HRC62-68 |

|

Material |

Premium Grade Steel |

|

Ld Ratio |

10-35 |

Superior Durability and Performance

Engineered with high hardness through heat treatment (60-70 HRC) and surface treatments like nitriding or hard chrome plating, these screw barrels deliver outstanding lifespan and wear resistance. The option for bimetallic alloy lining further enhances their ability to withstand high-stress production environments, making them suitable for demanding applications involving compounding, extrusion, and high-volume plasticizing.

Segmented Construction for Effortless Maintenance

The segmental, replaceable section design allows quick repairs or part replacement, reducing machine downtime and maintenance costs. This feature facilitates efficient upkeep, especially during continuous and heavy-duty operations, ensuring the extruder or injection moulding machine stays productive over extended periods.

Custom Solutions for Every Requirement

With flexibility in screw diameter, barrel length, mounting, and material, each screw barrel is tailored according to client specifications and machine drawings. This ensures perfect integration into various manufacturing setupswhether you require a new installation or replacement barrel, every unit is crafted for maximum operational compatibility and performance.

FAQs of Segmental Screw Barrel:

Q: How does the segmental design benefit maintenance and operation?

A: The segmental, replaceable section design allows individual segments to be easily replaced or repaired without disassembling the entire barrel. This reduces downtime, minimizes maintenance costs, and ensures smoother operation for plastic extruders and injection moulding machines.Q: What surface treatment options are available for the screw barrel?

A: You can choose between nitrided and hard chrome plated surfaces. Both options offer enhanced surface hardness (60-70 HRC), but hard chrome plating also improves corrosion resistance, while nitriding provides lasting wear resistance, suitable for rigorous plastic processing tasks.Q: When should I consider choosing a bimetallic alloy lining?

A: Bimetallic alloy linings are recommended when extreme abrasion or aggressive additives are present in your plastic processing. This option significantly extends the service life of the screw barrel in environments where standard alloy steels might wear prematurely.Q: Where is this screw barrel used in plastic processing machines?

A: These screw barrels are installed in plastic extruders and injection moulding machines, serving processes such as plasticizing, compounding, and extrusion. They are widely used in high-volume plastic production industries across various sectors.Q: What process does this screw barrel support?

A: The barrel is designed for both extrusion and injection moulding processes. It ensures high-efficiency melting, mixing, and homogenization of plastics, contributing to consistent product quality and high throughput.Q: How can I customize the screw barrel for my machine?

A: Customization is available according to client-provided drawings and specifications. Parameters such as barrel length, screw diameter, sectional design, and surface treatment can be tailored to suit your specific machine and operational requirements.Q: What are the main benefits of using this segmental screw barrel?

A: Key benefits include high wear and corrosion resistance, superior hardness, long working life, easy maintenance due to the segmented design, and adaptability for various applications and machine types, resulting in lower operational costs and enhanced productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screw Barrels Category

Injection Molding Screw Tips

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Hydraulic

Capacity : Up to 300 tons, depends on application

Product Type : Injection Molding Screw Tips

Material : Highgrade Alloy Steel

Chrome Plate Screw Barrel

Price 35000 INR / Piece

Minimum Order Quantity : 1 Set

Drive Type : Mechanical

Capacity : Depends on machine and usage

Product Type : Screw Barrel

Material : Alloy Steel with Hard Chrome Plating

Planetary Screw Barrel

Price 100000 INR / Set

Minimum Order Quantity : 1 Set

Drive Type : Electric

Capacity : 50500 kg/hr

Product Type : Planetary Screw Barrel

Material : Alloy Steel