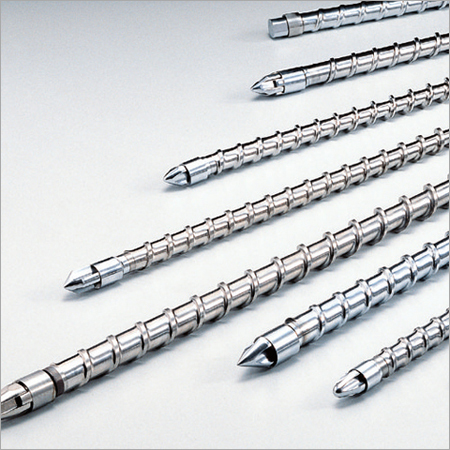

Chrome Plate Screw Barrel

Chrome Plate Screw Barrel Specification

- Application

- Plastic Extruder Machines, Injection Molding Machines, Rubber Machinery

- Cutting Speed

- Not Applicable for this product

- Power Source

- Mechanical / Driven by attached equipment

- Spindle Speed

- Depends on operational equipment

- Noise Level

- Low

- Tool Type

- Extruder/Injection Screw Barrel

- Product Type

- Screw Barrel

- Material

- Alloy Steel with Hard Chrome Plating

- Computerized

- No

- Automatic Grade

- Manual / Semi-Automatic

- Control System

- Manual

- Drive Type

- Mechanical

- Weight (kg)

- Custom (Varies as per dimensions)

- Dimension (L*W*H)

- Customizable as per machine requirement

- Capacity

- Depends on machine and usage

- Feature

- Hard Chrome Plated, Corrosion Resistance, High Wear Resistance, Long Service Life

- Color

- Silver (Chrome Finish)

- Structure

- Single or twin screw, customizable design

- Usage

- For processing a wide range of thermoplastics and thermosets

- Hardness

- HRC 58-60 after nitriding & plating

- Manufacturing Tolerance

- High precision maintained for close fittings

- Corrosion Resistance

- Excellent

- Surface Treatment

- Hard Chrome Electroplating to 0.03-0.05 mm thickness

- Service Life

- Extended, owing to anti-wear & anti-rust plating

- Compatibility

- Custom-made for various extruder and injection machine models

- Finish

- Precision ground and polished

Chrome Plate Screw Barrel Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- Set

- Delivery Time

- 45 Days

About Chrome Plate Screw Barrel

In order to attain clients' utmost satisfaction, we are affianced in offering a wide range of Chrome Plate Screw Barrel. This is precisely manufactured as per the set industry norms by utilizing premium quality materials and advanced techniques. The barrel offered by us is available in plethora of specifications to meet the exact needs of the customers. It has applications in plastic profiles, plastic injection, rubber production, food production etc. In addition, our provided Chrome Plate Screw Barrel is available at economical prices.

Features:

- Rust resistance

- Dimensional accuracy

- Easy to install

Specification

| Condition | New |

| Diameter (mm) | 20mm-200mm |

| Appliance | PVC, HDPE, PP, PE |

| Application | Plastics |

| Screw Straightness | 0.015 |

| Thickness | 2mm |

| Surface Roughness | Ra0.4 |

| Screw Type | Nitriding, Bimetallic, Chromeplate |

| Hardness | HRC62-68 |

| Material | Premium Grade Steel |

| Ld Ratio | 10-35 |

Superior Surface Treatment and Hardness

Each screw barrel undergoes hard chrome electroplating, delivering exceptional surface hardness (HRC 5860 post-nitriding). This process enhances resistance to wear, rust, and chemical corrosion, making it ideal for demanding environments and continuous production cycles.

Versatile Applications Across Industries

Designed for a broad spectrum of plastic extruders, injection molding machines, and rubber processing equipment, this screw barrel adapts to unique machine dimensions and operational needs. Its customizable structure supports manufacturers, suppliers, exporters, and service providers seeking reliable performance.

Long Service Life and Precision Engineering

Utilizing high-grade alloy steel and stringent manufacturing tolerances, the screw barrel ensures close fittings and extended service intervals. The precision-ground finish reduces friction and noise, contributing to a smoother machine operation over time.

FAQs of Chrome Plate Screw Barrel:

Q: How is the hard chrome plating applied to the screw barrel?

A: The screw barrel is surface treated using an electroplating process that deposits a layer of hard chrome (0.030.05 mm thick) onto alloy steel. This follows nitriding, resulting in enhanced hardness (HRC 5860) and improved corrosion and wear resistance.Q: What types of machines are compatible with this screw barrel?

A: This product is custom-made to fit an array of extruder and injection molding machines, as well as rubber machinery. Its dimensions and weight are tailored to specific requirements, ensuring compatibility and optimal performance on diverse equipment models.Q: When should I consider replacing my screw barrel?

A: Replacement is recommended when you notice reduced plasticizing efficiency, excessive wear, or increased machine downtime. The hard chrome plating and alloy steel construction ensures extended service life, minimizing the frequency of replacements compared to standard barrels.Q: Where can this screw barrel be used?

A: The barrel is suitable for use in thermoplastic and thermoset processing industries, including plastic extrusion, injection molding, and rubber manufacturing operations. It is ideal for applications requiring high durability, wear resistance, and corrosion protection.Q: What is the benefit of hard chrome electroplating for screw barrels?

A: Hard chrome electroplating significantly improves surface hardness, wear resistance, and corrosion protection, resulting in a longer-lasting component. This treatment also yields a precision ground and polished finish, contributing to low noise and efficient material flow.Q: How does the manufacturing tolerance affect performance?

A: Maintaining high precision in manufacturing tolerances ensures that the screw and barrel achieve close fittings, which decreases material leakage, enhances mixing quality, and maintains consistent output throughout the products lifespan.Q: What is the general usage process for these screw barrels?

A: These screw barrels are installed in extruder or injection molding machines and operated with manual or semi-automatic control systems. They process and transport thermoplastics or rubber entirely by mechanical means, facilitating the transformation of raw materials into finished products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screw Barrels Category

Segmental Screw Barrel

Price 50000 INR / Set

Minimum Order Quantity : 1 Set

Drive Type : Electric

Noise Level : Low

Tool Type : Plastic Processing Screw Barrel

Material : Alloy Steel / Nitrided Steel

Injection Molding Screw Tips

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Hydraulic

Noise Level : Low

Tool Type : Screw Tip

Material : Highgrade Alloy Steel

Planetary Screw Barrel

Price 100000 INR / Set

Minimum Order Quantity : 1 Set

Drive Type : Electric

Noise Level : Low Noise

Tool Type : Extruder Screw Barrel

Material : Alloy Steel