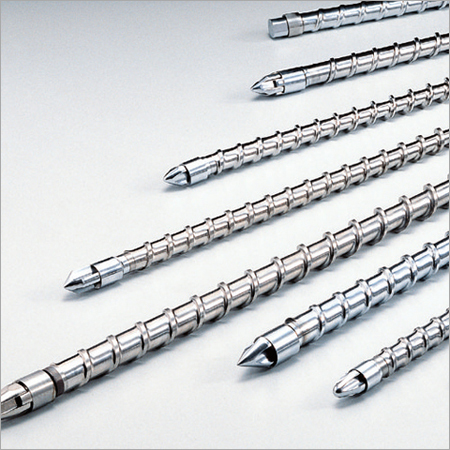

Planetary Screw Barrel

Planetary Screw Barrel Specification

- Spindle Speed

- Variable as per machine configuration

- Application

- Plastic Extrusion Machinery

- Tool Type

- Extruder Screw Barrel

- Noise Level

- Low Noise

- Power Source

- Electric

- Product Type

- Planetary Screw Barrel

- Material

- Alloy Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 220-440 V

- Weight (kg)

- 240-600 kg (Approx.)

- Dimension (L*W*H)

- Customizable as per requirement

- Capacity

- 50-500 kg/hr

- Feature

- High Wear Resistance, Corrosion Resistant, Precision Engineered

- Color

- Silver / Metallic

- Screw Diameter

- 25 mm - 200 mm

- Working Temperature

- Up to 400°C

- Screw Surface

- Nitrided / Hard chrome plated

- OEM Service

- Available

- Processing Type

- Plasticizing, blending, mixing, shearing

- Barrel Length

- Up to 6000 mm

- Finish

- Smooth surface finish

- Usage

- Single and twin screw extruders

- Hardness

- HRC 60-70

- Tolerance

- +/- 0.02 mm

- Design

- Customizable planetary system

Planetary Screw Barrel Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- Set

- Delivery Time

- 45 Days

About Planetary Screw Barrel

Planetary Screw Barrel is extensively demanded in diverse industries like automobile, petrochemical, mining and many others. This is manufactured under the observation of adept professionals using quality assured materials. The barrel is the most important part of the planetary kneading segments, mainly from the polymer melt kneading the role. Available in several designs and other specifications to fulfill the needs of our patrons, we offer this Planetary Screw Barrel at pocket friendly prices.

Features:

- Robust construction

- Longer life

- Excellent finish

Precision Engineering for Maximum Performance

With customizable diameters and lengths, our planetary screw barrels are manufactured to exacting standards, offering a fine tolerance of +/- 0.02 mm. Suitable for complex extrusion requirements, every screw barrel undergoes rigorous machining to endure high temperatures and intense working conditions, ensuring reliability and precision in every cycle.

Exceptional Durability and Adaptability

Constructed using robust alloy steel and advanced surface treatments like nitriding or hard chrome plating, these screw barrels provide high wear and corrosion resistance. The customization options extend from design to dimensions, easily adapting to various plastic extrusion machinery and processing applications while maintaining smooth operation.

Advanced Automation and Efficient Control

Each planetary screw barrel is designed for compatibility with automated systems and computerized, PLC-controlled operations. This integration enhances production efficiency, enables variable spindle speeds, and keeps noise levels low, all while supporting capacities of up to 500 kg/hr as per user requirements.

FAQs of Planetary Screw Barrel:

Q: How is the planetary screw barrel customized for different plastic extrusion applications?

A: The planetary screw barrel can be tailored in terms of diameter (25 mm to 200 mm), barrel length (up to 6000 mm), and overall dimensions to suit single or twin screw extruders operating within a range of processes, from plasticizing to shearing. Design, hardness, and finish can also be adapted per customer requirements through our OEM services.Q: What benefits does nitrided or hard chrome plating offer for the screw surface?

A: Nitrided and hard chrome plated surfaces significantly enhance the barrels wear and corrosion resistance, prolonging durability even under high-temperature conditions and abrasive processing environments. This ensures consistent performance, lowers maintenance needs, and extends equipment life.Q: When should a planetary screw barrel be selected for use in extrusion machinery?

A: Planetary screw barrels are ideal when high precision, robust wear resistance, and customizable configurations are required, such as in the plastic extrusion industry. Theyre especially suited for operations demanding reliable plasticizing, blending, and mixing capabilities under varying capacities and temperature conditions.Q: Where can these screw barrels be sourced and are they available across India?

A: As leading manufacturers, exporters, and suppliers, these planetary screw barrels are readily available across India. We supply to dealers, distributors, importers, and OEMs nationwide, ensuring prompt support and tailored solutions for the plastic extrusion sector.Q: What is the process involved in manufacturing planetary screw barrels?

A: Manufacturing involves precision machining of high-grade alloy steel, advanced surface hardening treatments (nitriding or chrome plating), strict quality checks for tolerance and hardness, and smooth surface finishing. Each barrel is designed to integrate seamlessly with computerized, automated production lines.Q: How is this planetary screw barrel used in plastic extrusion machinery?

A: It is installed as a core component of single or twin screw extruders for applications including plasticizing, blending, mixing, and shearing. Its customizable design allows for smooth feeding and melting of various plastics, optimizing output quality and efficiency.Q: What are the main advantages of using this product in extrusion processes?

A: Key advantages include high wear and corrosion resistance, precision engineering, low noise levels, compatibility with PLC control and automation, and the ability to handle a broad range of processing capacities and working temperatures, resulting in improved productivity and reduced downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screw Barrels Category

Segmental Screw Barrel

Price 50000 INR / Set

Minimum Order Quantity : 1 Set

Capacity : Custom / Machine specific

Computerized : No

Spindle Speed : Variable / Depends on Machine Design

Cutting Speed : N/A (Not applicable to screw barrels)

Injection Molding Screw Tips

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Up to 300 tons, depends on application

Computerized : No

Spindle Speed : Variable (as per machine setup)

Cutting Speed : High

Chrome Plate Screw Barrel

Price 35000 INR / Piece

Minimum Order Quantity : 1 Set

Capacity : Depends on machine and usage

Computerized : No

Spindle Speed : Depends on operational equipment

Cutting Speed : Not Applicable for this product